Home Products Light-Absorbing Materials Tsingcarbo® Black

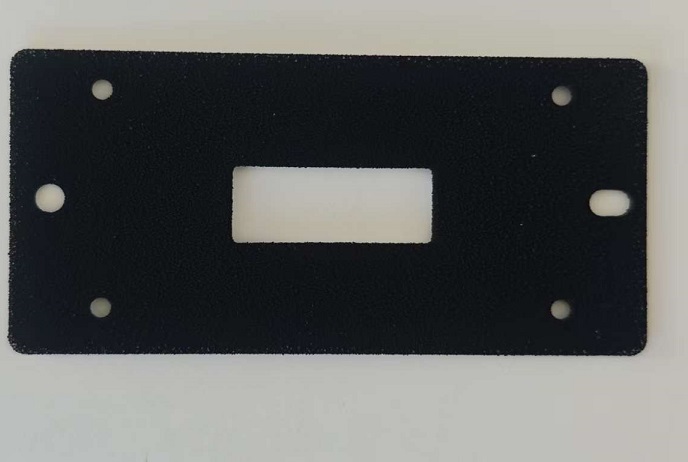

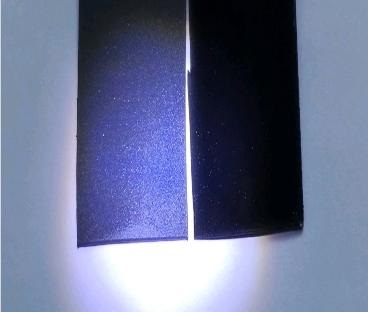

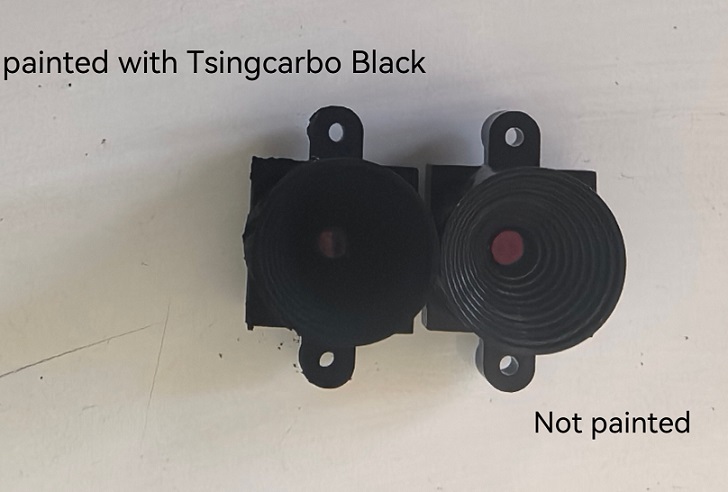

We has developed a light-absorbing coating called Tsingcarbo® Black by porous carbon. This coating achieves up to 99% light absorption across the 200-2500nm wavelength range. It exhibits high adhesion, does not shed particles, and can be applied via spraying. It is suitable for various substrates, including plastics and metals.

Reliability Test:

|

Item |

Test Standard / Technical Requirement |

Test Result |

|

Adhesion |

The coated sample is placed horizontally. On its surface, 10 parallel lines spaced approximately 1mm apart are cut in both directions to form a grid of 100 squares. A piece of 3M tape is firmly applied over the grid and then rapidly pulled off. The result is rated as 5B |

PASS |

|

High Temperature Test |

Place the coated specimen in an oven and bake at 200°C for 24 hours. The coating must exhibit no blistering, cracking, or peeling |

PASS |

|

QUV (UV) Weathering Test |

Refer to Test Procedure A specified in GB/T 2423.24-2013. Using a 24-hour cycle consisting of 8 hours of UV exposure followed by 16 hours of no exposure, perform 3 such cycles. After the test, a visual inspection shall show no deformation, cracking, peeling, or discoloration of the sample's appearance and structure. The color difference (ΔE) value shall be ≤ 2. |

PASS |

|

Low Temperature Storage Test |

Test temperature: -40°C for a duration of 48 hours. After the test, allow the specimen to recover under standard atmospheric conditions for 1 to 2 hours. The coating must exhibit no blistering, cracking, or peeling. |

PASS |

|

High Temperature Storage Test |

Test temperature: The maximum storage temperature (+80°C) is maintained for 48 hours. After the test, allow the specimen to recover under standard atmospheric conditions for 1 to 2 hours. The coating must exhibit no blistering, cracking, or peeling. |

PASS |

|

Damp Heat Test |

Place the coated specimen in a constant temperature and humidity chamber at 90% relative humidity and 70°C for 72 hours. After the test, let it stand at room temperature for 6 hours before inspection. The coating must exhibit no blistering or peeling. |

PASS |

|

Salt Spray Test |

Place the coated specimen in a salt spray test chamber and continuously spray with a 5% sodium chloride solution at 35°C for 48 hours. After the test, let it stand at room temperature for 24 hours before inspection. The coating must exhibit no blistering or peeling. |

PASS |

|

Thermal Shock Test |

Test temperature: -40°C to +80°C. Temperature transition time: ≤ 30 seconds. Dwell time at high and low temperatures: 120 minutes each. Number of test cycles: 6 cycles. |

PASS |

Application Process:

|

Primer Application |

||

|

Product Name |

Primer |

Hardener |

|

Mixing Proportion |

100 |

3 |

|

Important Note |

Spray after thorough mixing |

|

|

Filtration Mesh |

Filter through a 200-mesh screen |

|

|

Important Note |

Must be used up within 2-3 hours after mixing |

|

|

Nozzle Diameter |

1.5~1.8mm |

|

|

Air Pressure |

0.3 ~ 0.5 MPa |

|

|

Spray Technique |

Wet Spray |

|

|

Dry Film Thickness (DFT) |

5~ 10μm |

|

|

Curing Condition |

15 min at 70°C |

|

|

Topcoat Application |

|||

|

Product Name |

Topcoat |

Thinner |

Hardener |

|

Mixing Proportion |

100 |

70 |

20 |

|

Important Note |

Spray after thorough mixing |

||

|

Filtration Mesh |

100 mesh |

||

|

Important Note |

Must be used up within 2-3 hours after mixing |

||

|

Nozzle Diameter |

1.5~1.8mm |

||

|

Air Pressure |

0.3 ~ 0.5 MPa |

||

|

Spray Technique |

Adjust the spray gun for a slightly higher fluid delivery. Apply the coating in 5 to 6 passes, avoiding a wet spray technique. |

||

|

Dry Film Thickness (DFT) |

50 - 100μm |

||

|

Curing Condition |

Cure at 70°C for 30 minutes |

||

|

Packing Condition |

Pack after cooling |

||

Precautions

1.Prior to coating, the substrate must undergo surface pretreatment, which involves the removal of surface oils and contaminants, followed by the spraying process

2.After mixing, the product requires continuous pneumatic stirring within the mixing container to prevent settling of material, which ensures uniform spray application.。

3.Testing can be performed after letting the coating stand at room temperature for 72 hours, or alternatively, after accelerated curing by baking at 80°C for 4 hours.。

4.Storage: The coating has a shelf life of 6 months when stored in a cool place (15-30°C) in its original, unopened container.

Note: The above information represents average values derived from laboratory tests and is not intended as a product specification. Data may vary depending on different testing methods. Customers are advised to conduct their own trials and evaluations prior to selecting a suitable product.

Name: Jimy Ji

Mobile:+86 18915768767

Tel:+86 13646226232

Whatsapp:8615370757815

Email:sale@tsingcarbo.com

Add:No.5, Wujing Road, Economic and Technological Development Zone, Kunshan, Suzhou, China